NEMO-HD, Microsatellite for Earth Monitoring and Observation – High Definition, is a high performance multispectral Earth observation microsatellite that enables frequent and cost-effective remote sensing applications, exploitable in ecology, agriculture, forestry, land cover mapping, urbanism and maritime, as well as for monitoring climate changes, natural disasters and use of natural resources.

The Project

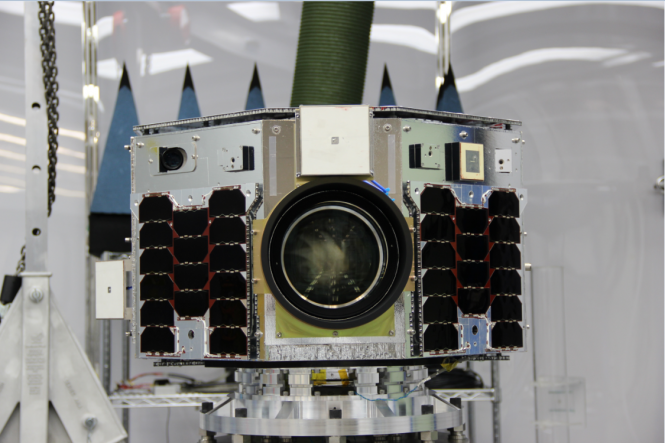

SPACE-SI, the Slovenian Centre of Excellence for Space Sciences and Technologies, in collaboration with UTIAS/SFL, the University of Toronto Institute for Aerospace Studies/Space Flight Laboratory, developed NEMO -HD, a 72 kg microsatellite (60x60x30 centimeters) for Earth monitoring and observation. The microsatellite designed for real-time video streaming and imaging, embeds optics of two of the main Italian companies in the Optical sector, Optec S.p.A. and Tecnottica Consonni S.r.l.

This next generation microsatellite, with a Made in Italy Optical System, is capable of resolving a Ground Sampling Distance (GSD) of just 2.8 m. The GSD, in Earth Observation, is the most popular spatial resolution performance parameter that all new optical earth observation instruments’ providers are pushing.

The GSD is a value scale capable of measuring the size, in linear meters, of an object or an area on the earth’s surface starting from an image taken from space. This means that the bigger the GSD value is, the less are the details visible in an image; as example, a GSD of 15m means that one pixel in the image represents linearly 15m on the ground.

The further the satellite from the earth and the larger the pixel size; to compensate for the bigger GSD, due to the NEMO-HD altitude of 600 km, it has been necessary to improve its optics and increase the focal length. The resultant is a Ground Sampling Distance of just 2.8 m, which means the capacity to discriminate between objects that are 2.8m or further apart.

With NEMO-HD in the orbit, SPACE-SI achieved a very innovative and cost effective remote sensing system, according to the Slovenian Company, imagery and video data acquired by the agile microsatellite will be used to monitor agriculture, forestry, urban development, and marine transport.

Nemo’s equipment

The microsatellite, for its monitoring and observation mission, is equipped with two instruments:

- the primary is capable of imaging in four spectral bands at a pan-sharpened GSD of 2.8m, and covers a swath width of 10 km;

- the secondary one produces images at a GSD of 40m and a much wider field of view.

In addition to still imaging, both primary and secondary instruments capture high definition video at 25 frames per second, to capture color HD (1920 x 1080 pixels) video at two resolutions: high resolution at 2.8 m GSD and low-resolution at 75 m (or better) GSD.

The module can be operated in real-time imaging mode, allowing an operator at mission control on the ground to view the video feed as it is captured. If an event or feature of interest is spotted, a command can be sent to the satellite to collect a still image of the area.

NEMO-HD represents a breakthrough in next-generation, compact microsatellite missions, and pushes the envelope of what can be accomplished by a small microsatellite in Earth observation.

The challenge

- NEMO-HD must capture still images at four spectral bands, (450-520 nm, 520-600 nm, 630-690 nm, and 760-900 nm), with a minimum Signal-to -Noise Ratio (SNR) of 75, assuming a 30% target reflectivity; and the Optical System is required to have a minimum Modulation Transfer Function (MTF) of 0.10.

- The Optical System required 11 Optical Elements and a perfect alignment of all the sensors, with a precision of 1/5 of pixel (whose dimension are 1,67×1,67 micron), in order to be apochromatic and reduce the lateral chromatic aberration,.

- The system needs to maintain the performances in the entire thermal range of Space.

“NEMO-HD had been a very challenging project on both the designing and assembling point of view. Optec was able to achieve the required performances investing on innovative solution, such as an active focus compensation, and relying on partners whose expertise helped us. – Said Matteo Marmonti, Optical R&D of Optec S.p.A. – Tecnottica, for example, was fundamental in order to achieve the required optical characteristics of the lenses and, more important, in aligning and gluing each lens into its own barrel with a precision of less than 10’’ in tilt and 10micron in decenter. The success of the project is the success of the entire Optica Group team.”

The Solution

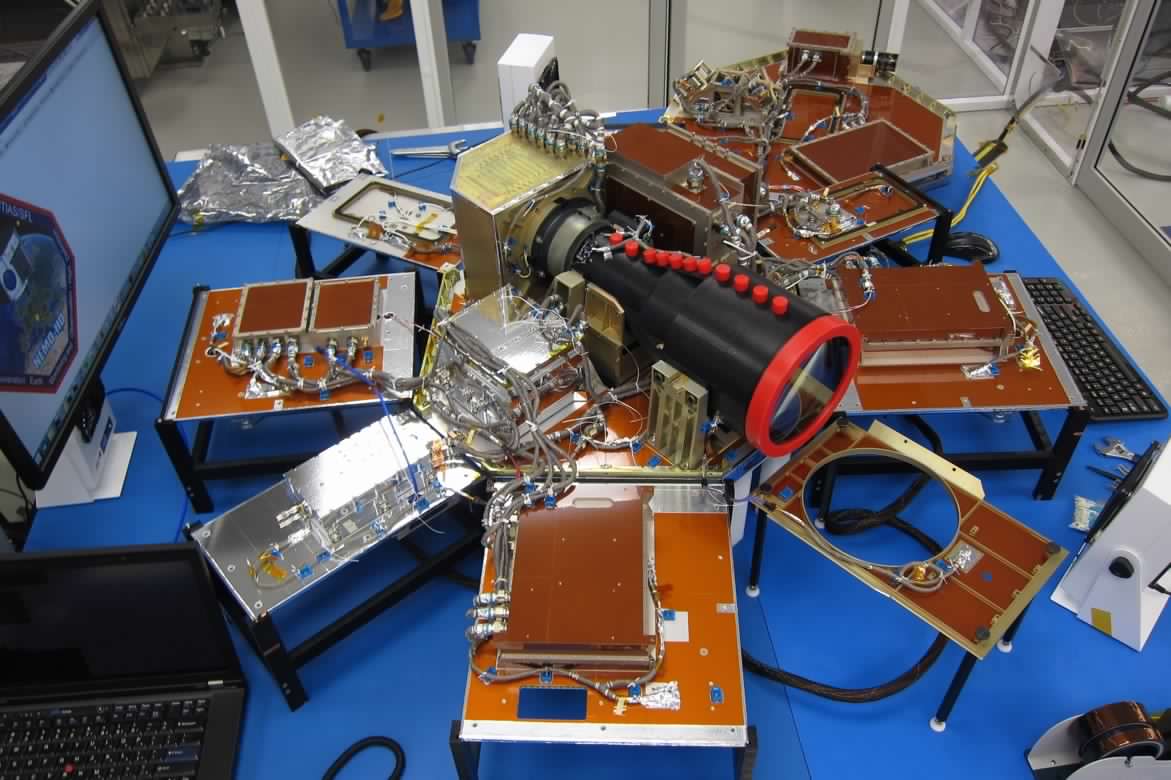

Optec, Italian manufacturer specialized in Optics, has been selected to design and produce NEMO’s Optical Systems for Space-SI, including the Camera responsible to capture the still images at four spectral bands.

To manufacture some sub-components, Optec selected, among the others, Tecnottica Consonni, long-standing partner in the development of Optical Components and Systems specifically designed for the aerospace market.

The Camera assembly has been optimized to handle an image with a size of 12mm diagonal, and to allow the camera to split the light into the following bands:

- HRS-PAN: 390 – 900nm, with trimming filter GG435

- HR-HD: 390 – 900nm, without trimming filter

- Blue: 420 – 520nm, with trimming filter GG435 + FF02-470/100-25 (by Semrock)

- Green: 535 – 607nm, with trimming filter GG395 + FF01-571/72-25 (by Semrock)

- Red: 634 – 686nm, with trimming filter GG395 + FF01-660/52-25 (by Semrock)

- NIR: 750 – 960nm, with trimming filter GG395 + FF01-855/210-25 (by Semrock)

Engineering & Design

Optec engineered an Optical Arrangement to effectively double the focal plane and allow each sensor to be placed as close as possible to each other, while permitting the physical separation required by their electrical interfaces. The first two outputs are wide band outputs and share the same focal plane, extract 30% of the incoming light and direct the resulting image into two sensors on the focal plane. The remaining 70% of the incoming light is directed to a four channel prism, which divides the light into four spectral bands.

Optec designed and placed in front of the camera a Dioptric Diffraction Limited Telescope, with a focal length of 360mm, a F/N of 2.3 and an active focus mechanism, to maintain diffraction limited performances from 20km up to infinity and in the entire thermal range -20°C / +60°C.

Optical Components

Tecnottica realized Absorption Filters to remove part of the signal from UV light and SWIR light, and all the lenses embedded on the telescope, in detail manufactured:

- A Spherical Plano-Concave lens (PCC) with a diameter of Ø 128 mm

- Three Spherical Biconvex asymmetric lenses (ABL) of a diameter of Ø 84 mm

- One Spherical Biconvex asymmetric lens (ABL) of a diameter Ø 109 mm

- One Spherical Biconcave lens (BCC) of a diameter of Ø 109 mm

- Two Spherical Biconcave lenses (BCC) of a diameter of Ø 72 mm

- An Achromatic doublet of a diameter of Ø 84 mm

Tecnottica is in fact specialized in manufacturing Optical Components to the highest quality and strictest tolerances, specifically optimized for Aerospace industry requirements.

The company expertise, Optical System Design, advanced in-house manufacturing and testing equipment are ideal for:

- delivering Optical Components used for diverge an incident beam or to increase the focal length of a previously known system;

- realizing a wide range of Spherical Lenses with diameters between Ø 3 mm and Ø 310 mm of any radius of curvature and shapes;

- Polishing high quality levels of surfaces;

- obtaining Surface Accuracy up to λ/20, tested and certified,

- guaranteeing Optical Centering with values less than 30’’.

The two Italian Manufactures, together, realized the First Diffraction Limit System NOT Catadioptric with a 6-Channel Multispectral Rear View Camera.

Space-Qualified Systems

The resolution of an Optical Imaging System, such as the telescope and the camera, can be limited by factors such as imperfections in the lenses or misalignment, for this reason the entire Optical System needed the expertise of Tecnottica’s in Optical Centering and Polishing. An extremely High Degree of centration accuracy allowed a precise positioning of each component without harming them and the production of maximum performance optics, fundamental to grant a precision of 1/5 of pixel.

To maintain the performances of the System in the entire thermal range for the space application, all Optical Components have been treated with a specific Coating, whose realization was directly managed by Tecnottica.

“Being involved by Optec in the creation of the Optics for this project certainly contributed to raise the quality level of our work. – said Angelo Fasoli, CSO of Tecnottica S.r.l. – The technical specifications required in the preliminary designs, at the beginning, seemed out of our reach, but through careful study we realized that it would actually be possible.

Conscious of our potential, we accepted the assignment and the results proved us right. Our precision optics department in synergy with our internal mechanical workshop team were able to develop dedicated tools and processes that allowed us to meet all technical requirements. What initially seemed out of reach allowed us to develop new skills that we will now make available for other similar projects”.

To obtain the expected results, and produce the First Active Focus Mechanism embedded on a space satellite, required more than 1 year of tests, a minute search of the proper materials and lubricants, specifically designed and produced for the Space environment, meticulous manufacturing, assembly and an impeccable quality control.

The Space Mission

The microsatellite NEMO-HD was launched on the 2nd of September 2020 in Kourou French Guiana, as a passenger payload of the vehicle VEGA SSMS (Small Spacecraft Mission Service), an Advanced generation European carrier rocket of Arianspace developed by the Italian Space Agency (ASI) and the European Space Agency (ESA).

VEGA rocket successfully launched 46 nanosatellites and 7 microsatellites, including NEMO-HD, that separated from the rocket 40 minutes after takeoff and successfully established the first contact with Earth the same morning.

Space-SI released the first multispectral image captured by its NEMO-HD Earth observation microsatellite, just 16 days after launch.

“NEMO-HD is enabling a new Earth observation concept by combining multispectral and video imaging from space. This can be controlled interactively in real time if needed when NEMO-HD is flying in the range of a ground station,” said Prof. Tomaž Rodič, CEO of SPACE- SI.

“With NEMO-HD successfully in orbit, we have achieved a very innovative and cost-effective remote sensing system which combines the agile microsatellite with our transportable ground station system, STREAM, and the advanced EO data processing chain, STORM.”

https://www.michelasevergnini.it