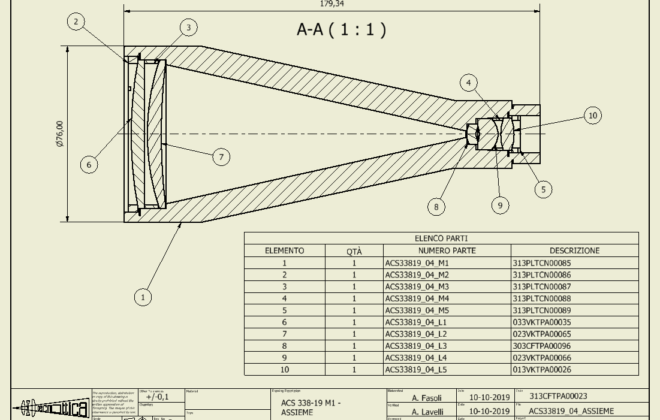

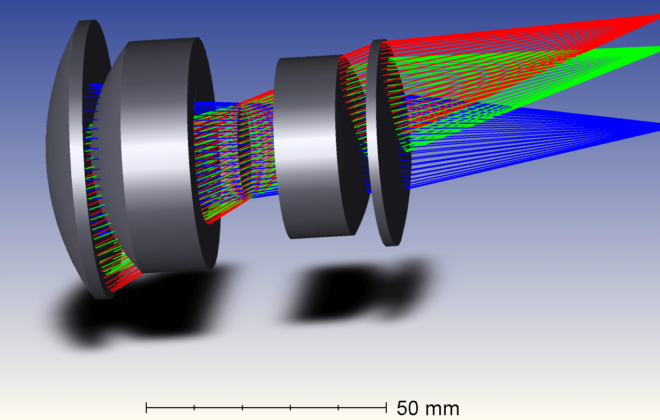

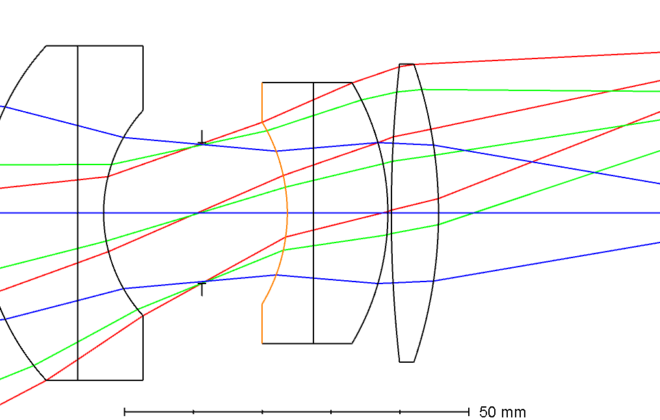

OPTICAL DESIGN

With the help of the most advanced software and optical CAD, we are able to provide the customer with complete support in the design and engineering of individual optical elements and complete optical systems. The design is completed and accompanied by an accurate analysis of processing tolerances in order to conceive the birth of a product that is first of all industrializable and cost-optimized. To companies that are already independent in mechanical design, we provide direct support for the integration of the optical project within their mechanical system; on the contrary, we are able to provide directly - or through the help of external partners depending on the complexity of the project - an aid also with regard to the analysis and design of the mechanical parts to be combined with the optical elements.

PROTOTYPING

We think that it is fundamental to offer to customers a rapid and efficient service of prototyping, able to offer quality products ready to be tested in the shortest possible time. For this reason, after our optical designs or after we got an order for prototypes, we can immediately start the prototypes production in a separated production area. This area allows us to handle productions which have to be necessarily completed within a few weeks from their start. In a minimum of 2 weeks and up to a maximum of 8 weeks, we are able to provide to our customers complete and coated optical prototypes.

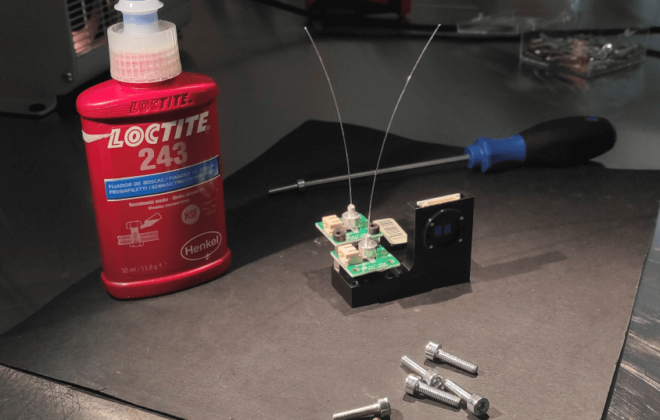

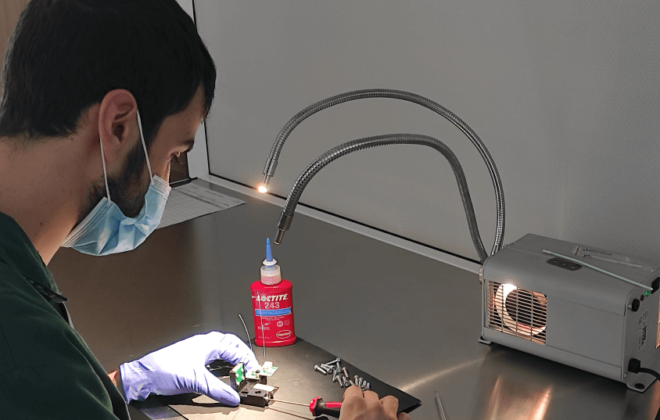

ASSEMBLY

The assembly of the various components of an optical system is perhaps the most delicate phase of the entire production. Tecnottica, thanks to an area equipped with laminar flow and air-conditioned hoods, is able to glue several lenses of the same optical group (achromatic doublets, triplets ...) and place a small "assembly line" to manage assemblies of optical, electrical and mechanical components from the customer to the finished optical system.

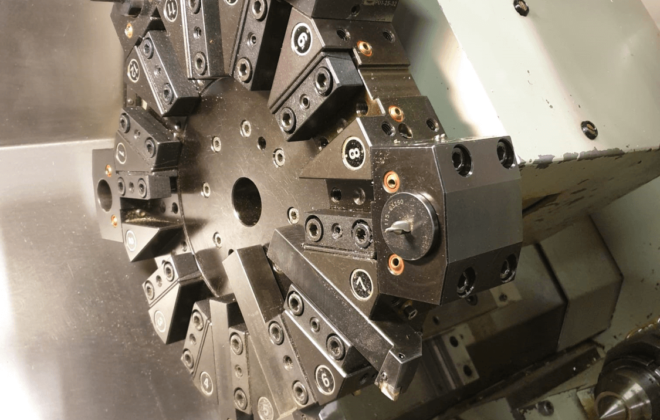

HIGH-PRECISION MECHANICAL WORKSHOP

Thanks to the mechanical workshop within the production department and our modern CNCs, Tecnottica also offers the ability to quickly produce pliers and polishing patinas for any radius.

SURFACE TREATMENTS

Tecnottica designs and supplies high performance optical coatings, which can be customized according to customer requirements:

- ANTI-REFLECTIVE, REFLECTIVE AND DICHROIC COATING

- Possibility of measuring the effectiveness of the coating with a spectrophotometer operating in the range of 190 -4900 nm

- COATING FOR SPECIAL FILTERS

- CHEMICAL AND THERMAL TEMPERA

- BLACK PAINTING OF THE EDGES

CERTIFICATIONS

The machinery and equipment of Tecnottica's metrology department allow us to carry out measurements and certify products to our customers.

Tecnottica is certified according to the ISO 9001 Quality Management System regulations to guarantee that the company is able to respond consistently and comprehensively to customer expectations.

Certificato_Tecnottica_Consonni_Srl_ISO_9001

Tecnottica Consonni is certified according to the UNI EN ISO 14001 environmental certification, which certifies that the company has an adequate management system to keep the environmental impacts of its activities under control.

CUSTOMER CARE

Tecnottica's philosophy, successfully carried out over the last 50 years, is centered on the concept of providing the customer with a finished product, made entirely at our facilities, which is able to exhibit first of all the best possible quality, compatibly with the applications to which it is designated.

We usually work directly and in close contact with our customers, creating specific products modeled according to the needs and qualities required by each one.

Precisely for this reason Tecnottica does not have a real catalog, but customizes its products from time to time while maintaining adequate and firm confidentiality, to prevent an object developed successfully and in collaboration with a customer from being exploited by third parties.