Prototyping and Optomechanical Design

Tecnottica’s production targets various application sectors, including Aerospace, Biomedical, Machine Vision, Automotive, and Lighting. It develops customized optical solutions by creating products that are modeled based on the needs and quality requirements of its clients.

Prototyping and Optomechanical Design are two fundamental aspects of developing any personalized product. Their combination allows the creation of high-quality products that are ready for mass production.

Prototyping enables the creation of a physical model of the product and validates the design through laboratory testing, verifies functionality and quality through field tests, and grants it function as expected.

Optomechanical Design focuses on optimizing the optical and mechanical performance of the product to obtain an ideal system that meets the needs of the client.

Prototyping

To design effective and precise systems that ensure the desired image quality and optical performance, Prototyping follows a multi-phase process that includes design, production, and validation.

Prototyping is entrusted to the Optical Designer, a specialized technician in Optical Physics, with in-depth knowledge of lens and optical material properties, and design tools, including design software.

The Optical Designer is responsible for:

- Design and development of optical systems, which may consist of lenses, mirrors, prisms, and other elements, engineered for various application areas.

- Testing and evaluating prototypes to verify that they meet specifications and are ready for mass production.

- Supporting production phases.

Design

Before being internally validated and approved by the client, a project goes through numerous processing stages, which often need to be repeated and reworked before producing the desired result.

Phase 1: Optical Simulation

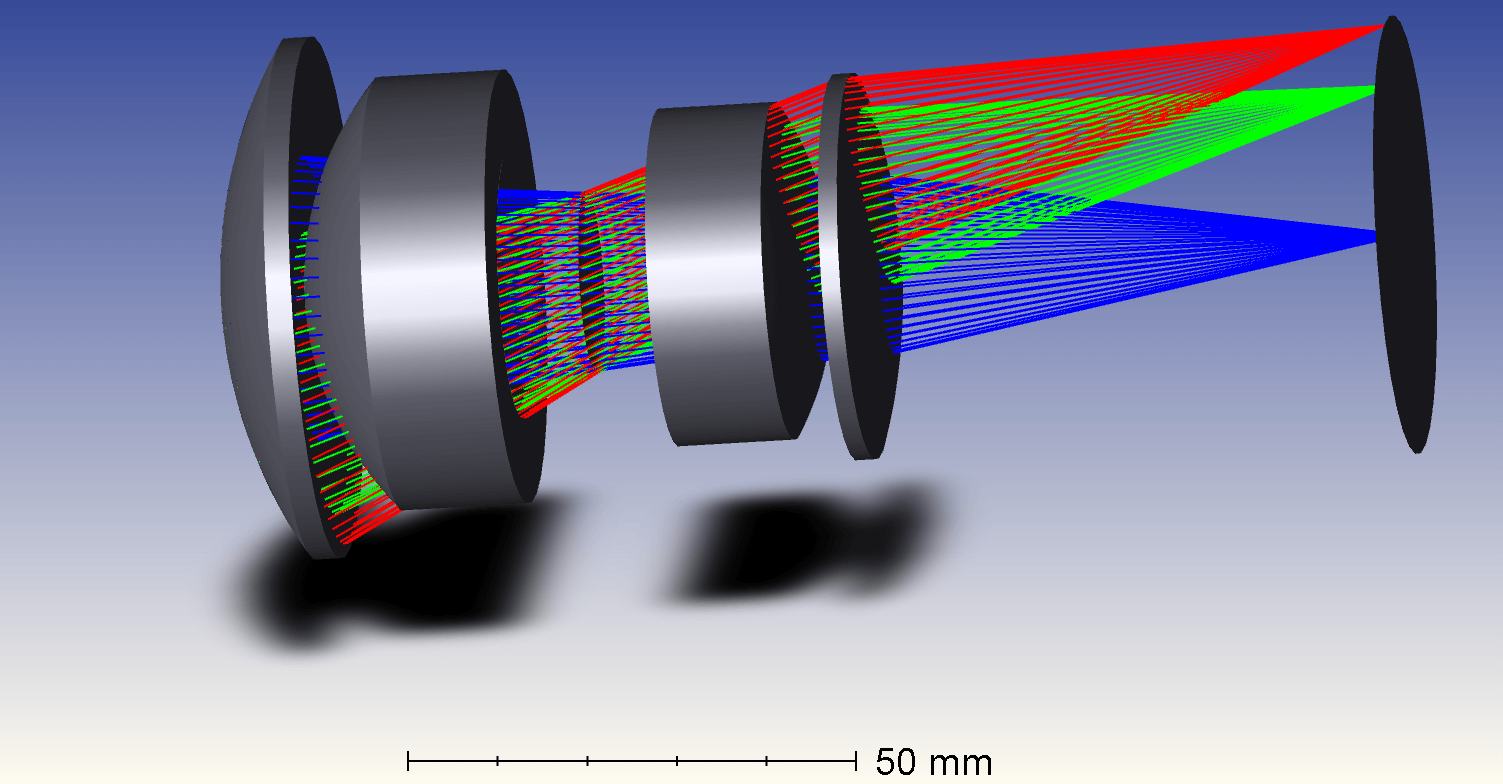

The first phase of the design is the responsibility of the Optical Designer and involves a graphical simulation created with an optimization CAD software (Zemax), specifically designed for the Optical industry. The software works with degrees of freedom and a merit function that, by keeping some variables fixed, allows playing with other parameters, such as lens geometries, glass types, wavelengths.

The software processes the entered data, analyzes tolerances, and returns a 3D image with a specific lens geometry.

There are in fact different lens designs capable of performing the same function, the program proposes the optimal one in theory, which has fewer aberrations, greater precision, and so on, however, as in all theoretical systems, the result often does not coincide with the design that is easiest to produce or feasible. Therefore the designer must evaluate together with the Production Manager costs and benefits and, identify the best design.

A fundamental and challenging part of optical design, but also mechanical design, is determine component tolerances, as they define the quality of the project itself. If they are too tight, production becomes impossible, if they are too loose, they undermine the quality of the project.

Phase 2: Assembly Simulation

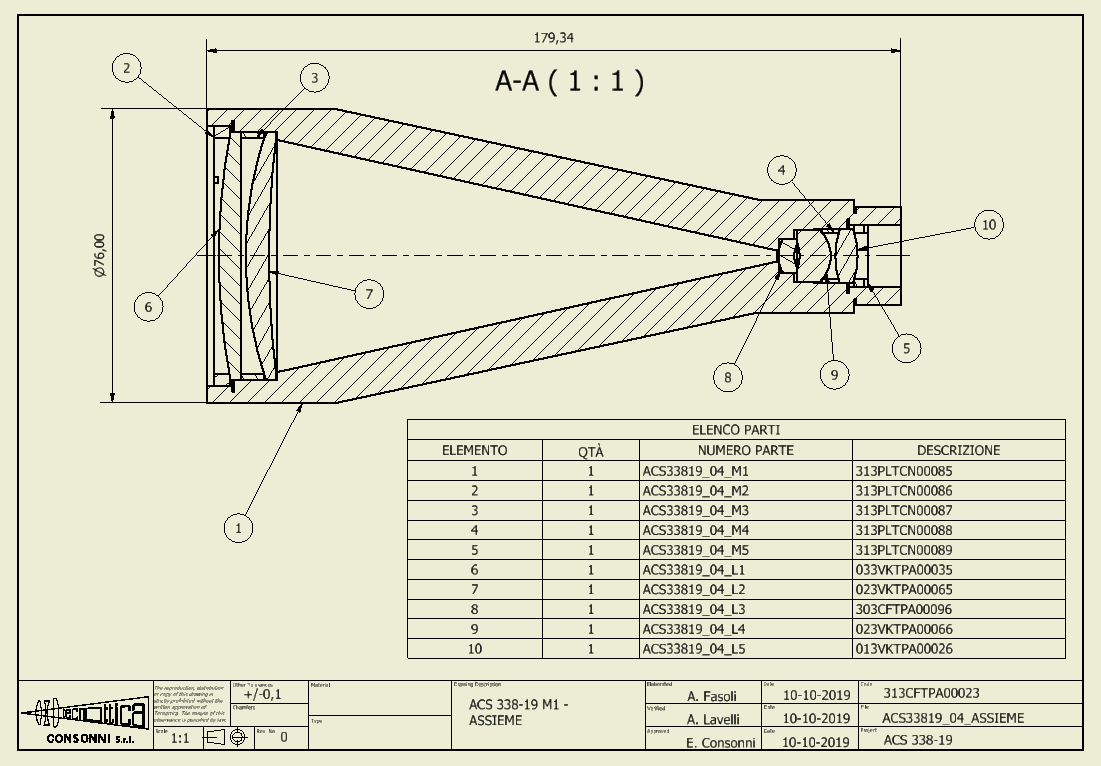

In this phase, the Mechanical Designer, through 2D drawings of the optics containing the lens profiles (in section), the distance between lenses, and ray tracing, is responsible for creating the Assembly Simulation.

Using data provided by the Optical Designer, he/she develops a 2D project with AutoCAD for the mechanical parts (spacer barrels, rings, etc.), a 3D drawing of the finished assembly with Inventor, rendering of the entire project including optics, and mechanical tables with their measurements, tolerances, threads, and external dimensions, which will be used by the Mechanical Workshop for production.

Phase 3: Material Acquisition

Once the tables have been approved by the client, the Optical Designer collaborates with Logistics to identify the glass defined by the software, or the closest one.

Meanwhile, the Mechanical Designer works with the Mechanical Workshop to identify the best materials (aluminum, plastic, etc.) for the mechanical parts, and to define the ideal finishing compatible with the optics.

If some materials are not suitable or available, the project may need to be revised from the beginning.

Production

The Production phase begins with the coding of individual components; where all lenses, spacers, nuts, and screws are identified with a unique code.

Follows the production of optics, which takes longer, particularly if they require coating.

Ends with the production of mechanical parts and any anodization, if necessary.

Each phase is followed by a meticulous cleaning of the components under Laminar flow boxes.

Assembly

The first assembly phase involves inserting the optics into their respective mechanics.

Follows the assembly of mechanical parts and the final one where all components are mounted to form the system, including any electronic parts provided by the customer.

Each phase occurs strictly under Laminar flow boxes and includes cleaning of individual parts and assembled parts.

Validation

The prototype is now ready, and the internal testing phase begins with measurements of focal length, centration of optics in mechanics, back focal, MTF, etc., based on required specifications.

Once all tests are passed, the prototype is carefully packaged and shipped to the customer, who will test it in the field.

If the customer does not approve the prototype due to any issues, the process returns to the design phase, and the optical or mechanical design is revised depending on the issue. Otherwise, the production of the required lots and quantities starts.

Optomechanical Design

Lenses, mirrors, prisms, and all optical components, in order to function correctly, either alone or within optical systems, must be mounted on appropriate supports that keep them in position or on mechanisms that allow for proper interaction. These supports are defined in optics as Assemblies or Optomechanical components.

Optomechanical Design is an important phase in the creation of a product, as it ensures that all components function properly together and that the product is robust and reliable.

The Engineer who is responsible for the Mechanical Design of the Assemblies is in charge of choosing the materials for the optomechanical components, designing, developing, and analyzing the components and their arrangement within a system.

Mechanical design of Assemblies uses various techniques and tools, including 3D modeling, computer-aided design (CAD), simulation, and prototyping. These tools enable the creation of precise models of the components and verify that they are compatible with each other and function properly within the system.

In mechanical design of lenses, in order to make the assembly functional and aesthetically pleasing, and especially to ensure that the lens fits perfectly with other components such as cameras, sensors,…, the Mechanical Designer must:

- design the individual elements that compose the system, such as lens supports, mirrors, prisms, and other optical elements;

- design automatic or motorized movement systems, such as focusing and zoom mechanisms, used in Spectroscopy, Marking, Optical Microscopy, Quantum Optics, Holography, Range finding, Lidar, Sensing, and Pointing Systems;

- ensure that the lenses are robust and reliable and can withstand mechanical, thermal, and environmental stresses.

In the Prototyping department of Tecnottica, we have two highly specialized figures who work together for the success of each project, the Optical Designer, Dr. Iari Gabriel Marino, and the Mechanical Designer, Dr. Francesca Brambilla.

Both work closely with Mechanical and Electronic Engineers to integrate optical elements into systems, to ensure that the final product meets customer specifications and grants excellent optical performance.

Tecnottica also has an internal Mechanical Workshop for creating mechanical components and their assembly. For particular or too large mechanical parts, the company collaborates with specialized mechanical workshops.

The company also offers a Prototyping Consulting service, which we will discuss in the next article.