Optical Components must have different properties based on the application and interference effect they are intended for; the shape, surface quality, and coating determine the performance of the component.

Almost every optical surface, made of glass, metals, ceramics or plastic, requires a coating. Optical Coating is a surface treatment obtained by adding different layers of various materials on the optical surface.

The way every optical component influences the interaction with light depends on the efficiency of its optical coating.

Type of Coatings

Each coating has a unique set of characteristics to ensure that the substrate is suitable for its application, such as reflect, split or reduce the incoming light, polarize, separate or combine wavelengths.

Coatings are made of a specific number of layers, from single to double or multiple, each level can have a different thickness (λ/4, λ/2…) and it can be composed by different materials, mainly metals and oxides.

The layers’ refractive index interacts with light differently when combined with others.

Optical Coatings are distinguished for specific application, such as:

- Anti-Reflection Coating (AR) to minimize surface reflection of substrates for highest transmission;

- Broadband (BBAR), Multiple (MAR), Wide Angle (WAR);

- High Reflection (HR) to maximize surface reflection: Single (HR), Double (DHR), Broadband (BBHR), Multiple (MHR), Wide Angle (WHR), Metal Coating (METAL);

- Partial Reflection (PR) to split or reduce incoming light: Single (PR), Double (DPR), Broadband (BBPR);

- Filter to separate or combine wavelengths: Long Wave Pass (LP), Short Wave Pass (SP), Notch Filter (NF), Multi Pass (MP), Band Pass (BP), Reflection Filter (REF);

- Polarizer to separate or combine the polarizations: Thin Film (TFP), Cube (CP), Broadband (BBPOL);

In Tecnottica we have a Coating Designer with 20 years of experience who designs and manufactures coating curves according to customer specifications and in relation to the substrate, surface imperfection tolerances, wavefront deformation tolerances, or particular operating environments, such as incompatibility with particular solvents, thermal operating ranges, and resistance to thermal shocks and radiation.

We are pleased to take the challenge.

Type of Substrate

The choice of the substrate material, shape and the surface quality in a optical system are as much important as the coating, in particular in low loss applications.

We treat all substrates marketed by the main world producers, ideal for use in various applications in the UV-VIS-SWIR and IR regions.

And we work with any kind of optical component and surface, such as plano-concave or plano-convex, plane windows, different shapes (cylindrical, rectangular, elliptical…), prisms, and others.

Production Methods

Coating are obtained by several physical deposition technologies, in Tecnottica we adopt the Electron Beam Evaporation (EBE) and the Ion Assisted Deposition (IAD), two of the most effective methods for the deposition of dielectrics, anti-reflective, and metals, granting exceptional directionality and a higher deposition rate.

Electron-beam evaporation generates a vapor cloud in the deposition chamber that precipitates against the substrate forming a thin film, by layering multiple optical coatings it is possible to achieve specific and unique reflective and transmissive properties.

Ion Assisted Deposition (IAD) is based on the EBE system with an additional Plasma Source that creates a denser micro structure on each layer able to eliminate thermal drift.

Our Production methods and procedures grant high uniformity and purity levels and translate to a high efficiency and a wide application range.

Our Coating Systems are:

- Optotech OAC-75F with EBE Technology – Electron Beam Evaporation

- Leybold Bühler Syruspro 1100 with IAD Technology – Ion Assisted Deposition

Controlled Environment

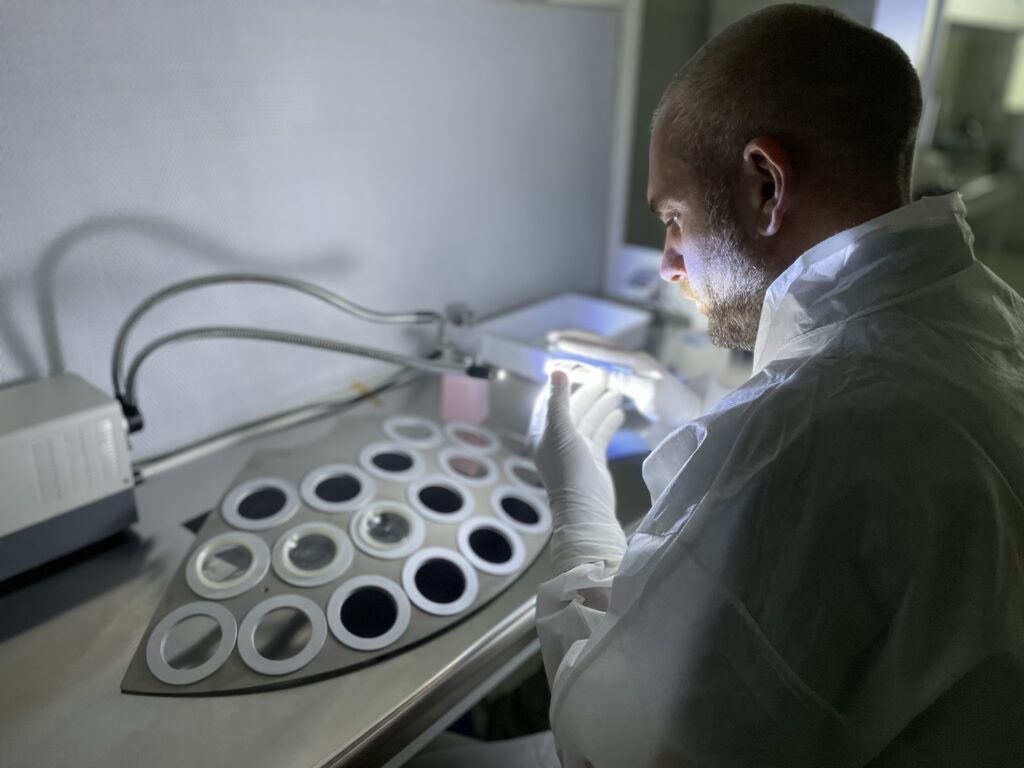

A grain of dust on the optical surface can compromise its functioning and the coating, for this reason at Tecnottica we pay particular attention to the critical environment in which we operate.

The temperature and humidity of the air are regulated to meet the operational needs of the production, furthermore the critical areas, where the lenses are prepared and the post-treatment inspection is carried out, are isolated to avoid any contamination and filtration of dust, molds and microorganisms.

The area is equipped with a very high level ISO 14644-7 certified Cleanroom with ISO 14644-5 certified Laminar Flow Modules, which guarantees high quality of the incoming air and prevents contamination; to access the clean room our skilled technicians must use appropriate garments as required in the norms above.

Metrology and Control

Our Quality Control Department inspect each component to grant that they are fully certified according to:

- the Standard ISO 9211, that defines the general characteristics, the test and measurement methods;

- the Standard ISO 9022, that defines terms relating to environmental tests

- the MIL-F-48616, that defines the inspection method for the Surface Quality.

For Space Applications we refer also to the Standard ECSS-Q-ST-70-17C, that verify the durability of the coating in hostile conditions.

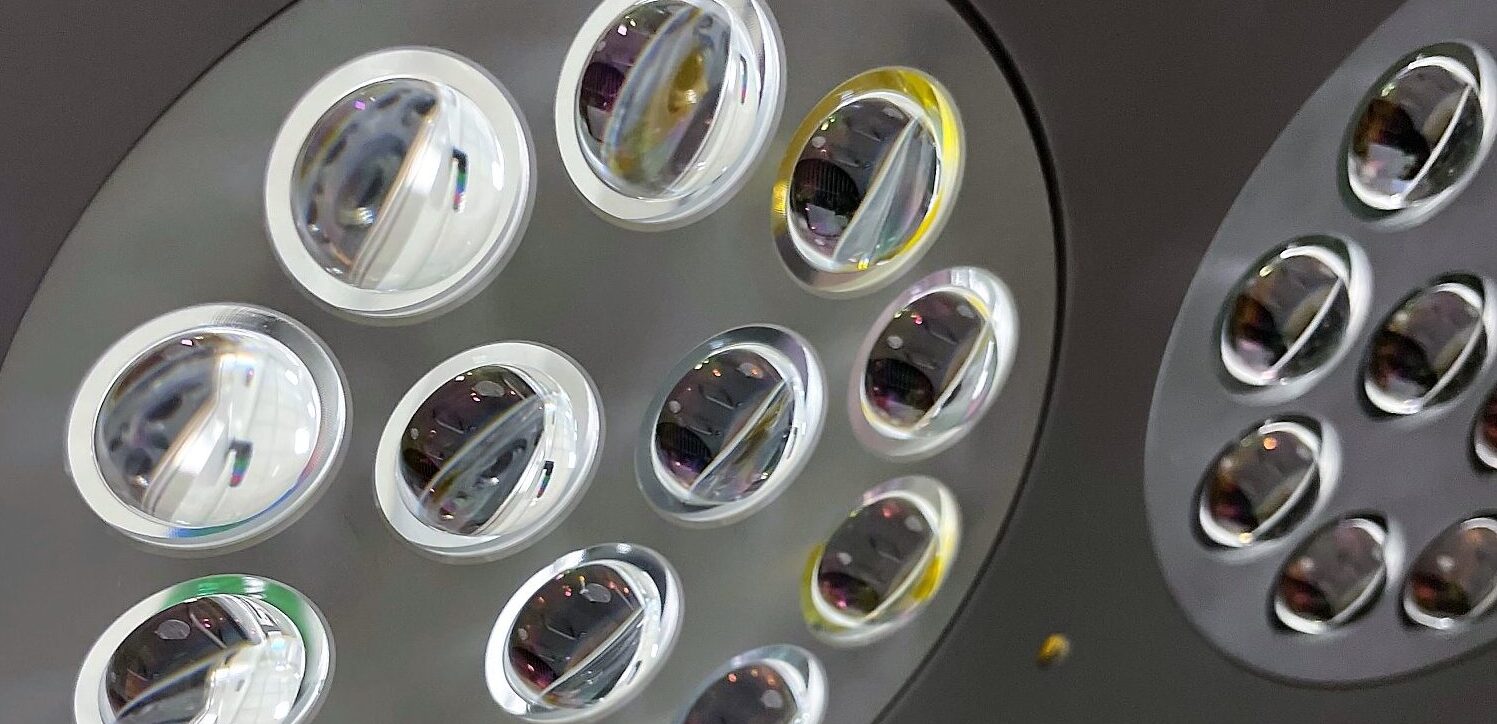

The coating curve of every lens is measured on a Witness Sample, a plane disk made of the same material as the optical component and having the same refractive index as the substrates, to analyze the coating curve and its spectrophotometric properties.

Our Coating Metrology department is equipped with:

- a Spectrophotometer Shimadzu IRAffinity-1S, for the range 1300nm-28micron,

- a Spectrophotometer Perkinelmer Lambda 1050+, for the range 175-3300nm.

Test Methods

Specific tests are conducted based on the environment in which the lens will be used to determine a coating’s characteristics.

Samples shall be cleaned and inspected before and after each test step to verify that the defects are in conformance with the coating specification.

Here a list of test methods we perform or manage in Tecnottica:

- ADHESION TEST assesses the adhesion quality and verify that the coatings is perfectly bonded with the substrate. The test procedure involves an adhesive tape attached to the coating (the external layer) and pulled off with a specific angle and strength, the test is repeated many times and results recorded as a measure of the adhesion properties of the coating.

- ABRASION TEST verifies that the coatings is not removed by cleaning and handling methodologies during its life time cycle. Two tests are commonly used: Moderate Abrasion and Severe Abrasion; in both test the coating is subject to numerous strokes with a pad across the surface; the coating showing no signs of scratches passes the test. What changes from one test to the other are the number of strokes, the force applied and the severity of environmental conditions the coating will be exposed to.

- SPECTROPHOTOMETRIC MEASUREMENTS tests the absorbance of the coating layers at various wavelengths and at different AOI (angles of incidence): in UV (Ultraviolet) region, Visible spectrum as well as IR (Infrared) region.

- CLEANING TEST is related to SOLVENT COMPATIBILITY and contemplate to wipe the sample with the test solvent. The Coating pass the test if no damage has been produced on the surface.

Some specific qualification testing for environments with harsh condition must be performed in controlled laboratories, all results are revised by our technical experts:

- ATOX OR ANY KIND OF PARTICLE AND UV TEST verifies the compliancy of the coating to radiation environment (space application);

- THERMAL VACUUM AND CYCLING TEST verifies the resistance of the coating to thermal cycles with high temperature changes and the compliancy of the coating in a vacuum environment (space application);

- HUMIDITY OR GENERIC ENVIRONMENTAL TEST verifies the coating can afford a rapid increase and decrease of temperature with a humidity equal to 90% (space application);

Our New Coating Department

The new highly specialized in-house Coating Department of Tecnottica was recently introduced to offer our customers a complete service and even higher quality finishes.

Insourcing the surface treatment allows us to satisfy the requests of our customers and guarantees us to trace each production batch, promptly provide the entire documentation with technical specifications and reduce production time.

The accuracy and precision of our tests, the particular attention to standards and quality control, that have always distinguished us, make certain that coating performance comply with specification and that our surface treatments can fulfill its function, no matter what environmental conditions they are exposed to.