The global Infrared Optics market has witnessed significant growth in recent years and is projected to continue expanding between 2023 and 2030, according to the recent study titled “Global Infrared Optics Market Trends and Insights”.

In the last 2 years, we at Tecnottica have observed a growing trend in the demand of IR Optics, the request of Filters and Lenses has increased by 20% for Defence, Biomedical and Laser applications.

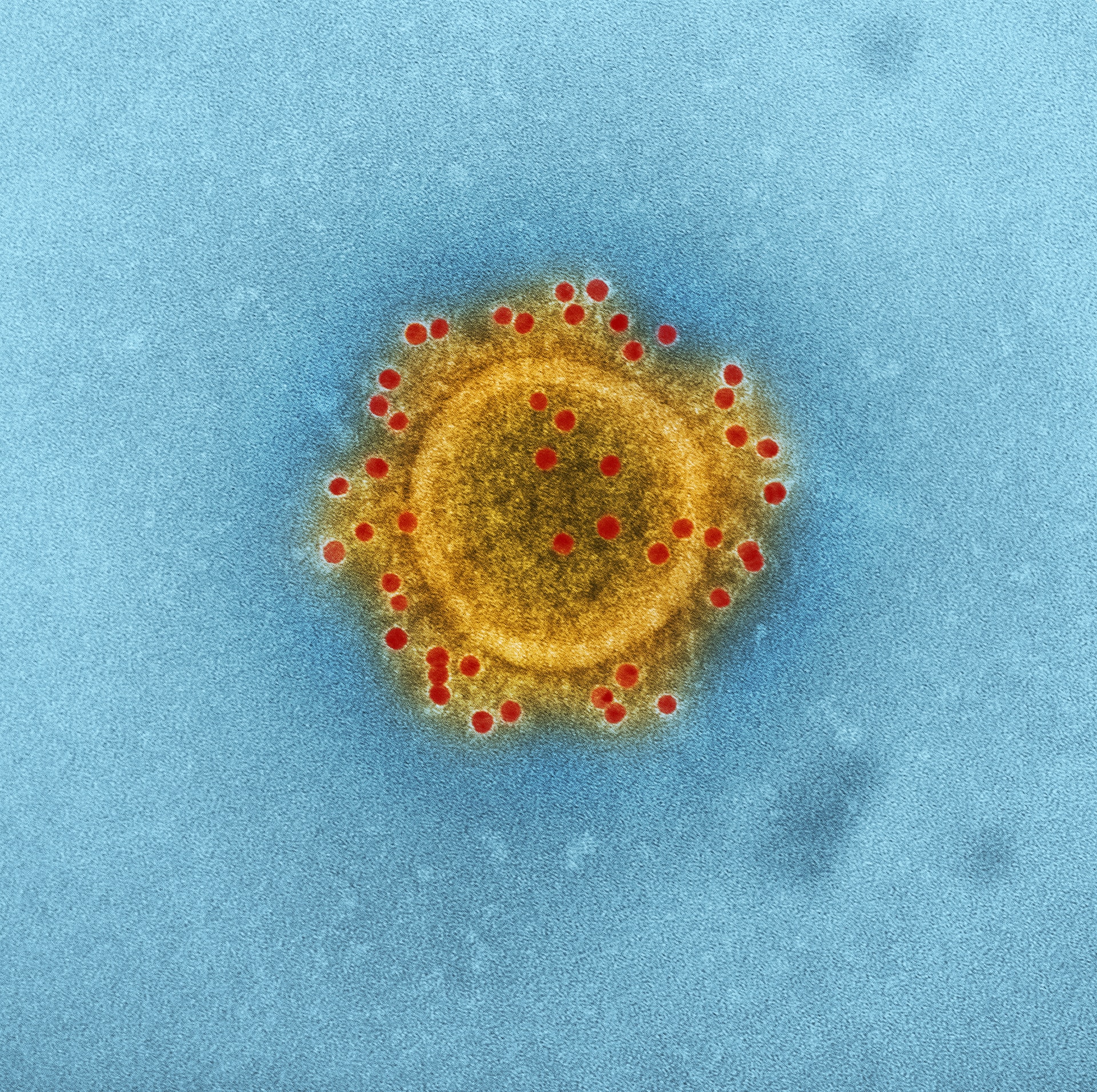

“We believe that the evolution of its fields of application will drive the growth of the Infrared Optics Market, in the next decades, especially in Medicine, Disease Biology and Defence”. – Said Angelo Fasoli, Chief Sales Officer of Tecnottica. “Infrared optics can diagnose and treat various diseases, such as cancer, diabetes and infections. Infrared optics can also enhance the defence systems’ capabilities, such as night vision and thermal imaging, by providing better resolution and sensitivity in low-light conditions. However, these are not the only fields of application for IR Optics. IR Optics can also be used for environmental monitoring, industrial inspection, astronomy, agriculture, and more“.

INFRARED OPTICS

Infrared (IR) radiation is a type of electromagnetic radiation that has wavelengths ranging from 700 nm to 1mm. This broad spectrum can be sub divided into four smaller regions: Near Infrared range (NIR) 700 nm – 900 nm, Short-Wave Infrared range (SWIR): 900 nm – 2300 nm, Mid-Wave Infrared range (MWIR): 3000 nm – 5000 nm and Long-Wave Infrared range (LWIR): 8000 nm – 1 mm.

Many Optical Elements and Systems are designed to work with infrared light, either exclusively or in combination with visible light. Some of the most common infrared optical elements are lenses, mirrors, beam splitters, prisms, optical filters, optical windows, polarizers, and Complex Optical Assemblies, that include high-performance infrared optics.

These Elements, and complex Systems, can be used to collect, focus or collimate light in the infrared spectrum.

MANUFACTURING INFRARED OPTICS

The production of Infrared Optics faces some challenges that need to be overcome to ensure their optimal performance, such as high cost, complex design, the choice and manipulation of the substrate, and environmental factors. Designing and manufacturing IR optics and systems require expertise and know-how to overcome these difficulties.

As manufacturer of Precise Optics and Systems, Tecnottica is able to design and produce various type of IR Optics, such as:

- plano-optics (i.e. windows, mirrors, polarizers, beamsplitters, prisms),

- spherical lenses (i.e. plano-concave/convex, double-concave/convex, meniscus),

- aspheric lenses (parabolic, hyperbolic, elliptical),

- achromatic doublets and triplets,

- assemblies.

Our plant in Calco is equipped with state-of-the-art machinery, such as Schneider Grinding and Polishing Machines (SLG50 Schneider, SPK100 Optotech and RSP40 Stock Konstruction), Optotech and Stock Konstruction Polishing Machines And Centering Machine Satisloh C50.

Our Metrology and Control department are equipped with measurement instruments to certify IR components, such as the Interferometers (XONOX VT 1200 or Optotech OWI 150XT and equipped with software Zygo MetroPro or Zygo MX); the 3D Optical Profiler System (ZeGage Pro) for non-contact scanning of surface profile with sub-nanometer precision; the Thickness measurer (XONOX CT200), used in production as well as in quality inspection for precise and robust contact measurement of lens central thickness on ground, polished and coated optics; the Spectrophotometer (Shimadzu IRAfinity-1S), for measuring the Coating Reflectance and Transmission in the range between 1300nm to 28 microns.

A specific know-how in the process of manufacturing IR optical components is required; in fact, to obtain high-precision products, that meet the standards, the polishing machines must be equipped with special abrasive pads, with very-fine-grain, and lubricated with abrasive liquids with specific concentrations.

At the end of the process, before Polishing Machines can be used to produce any optics in the VIS/UV region, must undergo a meticulous cleaning process up to two days, due to the materials used for producing IR optics pollute the machines.

Our advanced in-house manufacturing and testing equipment, allow us to produce IR lenses with the highest quality, certified and guaranteed by our tools, in very efficient manners, reducing waste and manufacturing defects.

We utilize our expertise to serve our customers in designing and manufacturing high-performance IR lenses and components, and we strictly control each optical component quality in production to ensure our high-quality standards and ISO 9001 certified process and meeting customs’ specific needs.

MATERIALS & SUBSTRATES FOR IR OPTICS

Infrared materials can be crystalline, glasses, semiconductors or metals, despite the huge quantity of substrate available only a dozen are used in the optics, imaging, and photonics industries to manufacture off-the-shelf components: Calcium fluoride, fused silica, germanium, MgF2, N-BK7, potassium bromide, sapphire, silicon, sodium chloride, Zns e ZnSe.

Some materials can be used for either IR or visible applications, for example fused silica, but for some purposes using an IR specific material can optimize the performance of the optic. IR substrates, in fact, have their own unique attributes that distinguish them from each other; they vary in their physical characteristics, in particular transmission and index of refraction and dispersion.

Also, the cost of the substrate is an important element to keep in mind when selecting the material, for example Germanium is quite expensive, while Silicon is cheaper than other IR optical materials.

The Optical Designer must select the most suitable material for any IR application by knowing their benefits. For example Germanium with high refractive index is typically used in IR imaging systems, Silicon is used in MWIR and LWIR systems that require an excellent transmission and a lack of birefringence, Magnesium Fluoride has a Low Index of Refraction and a good transmission from Visible to MWIR is ideal in windows, lenses, and polarizers that do not require anti-reflection coatings.

FIELDS OF APPLICATIONS OF IR OPTICS

Infrared Optics are mainly used in instruments that require thermal imaging, spectroscopy, and laser; IR Optics have a wide variety of applications in different sectors, such as Defence, Security/Surveillance, Industrial, Medical and R&D. Some examples of these applications are tracking/targeting systems, predictive maintenance, monitoring of high temperature industrial processes, thermography, flame detection and quality control/inspection.

One of these applications is interferometry, which relies on IR technology to investigate and extract information from electromagnetic waves in many fields, such as Astronomy, Metrology, Oceanography, Seismology, and Photonics.

Another application is spectroscopy, which studies the absorption and emission of light by matter and has a direct application in Chemistry, Medical Instrumentation, and Research Laboratories. Spectroscopy is mainly used for tissue analysis, human/animal fluid analysis, and glucose monitoring.

Laser instrumentation also relies on infrared optics, such as CO2 laser systems, MWIR laser systems, and IR laser systems.

Infrared Optics are also required for infrared imaging and vision applications, such as infrared viewers, thermal imaging, and rugged IR imaging.

IR lenses have been widely used in surveillance cameras, IR zoom systems, IR thermal display, and temperature detectors, mainly used in Safety and Security industry.

IR Optical filters are critical components for Machine Vision applications, they are used to maximizing contrast, improve color, enhance subject recognition and control the light that’s reflected from the object being inspected.

Tecnottica offers a wide variety of high performance IR optics by upholding the highest manufacturing and ISO standards spanning all IR spectral bands, near-infrared (NIR), short wave infrared (SWIR), middle wave infrared (MWIR) and long wave infrared (LWIR) spectra.

We produce a vast selection of lenses, windows, mirrors, assemblies, and other optics tailored for infrared (IR) applications. We apply specific coatings for use in harsh environments to MWIR and LWIR thermal optics. We design and manufacture IR imaging lenses, fixed focal length lenses, zoom lenses, beam expander, spherical lenses, aspheric lenses and Complex Systems.

We successfully work all known materials in the IR region, from standard optical glasses for lenses, windows and prisms, up to more precious optical glasses at high index and low dispersion, fused silica and IR The wide range of available substrate materials with high transmittance and efficiency (Germanium, Silicon, Zinc Selenide, Sapphire, Calcium Fluoride, and many more). Thanks to a direct raw material acquisition service and to a huge in-house stock, we are able to shorten the production timings.

Our IR optics feature a large field of applications and can meet customers need for industrial, medical, life science, defense applications.

Thanks to our technical and manufacturing expertise, along with specialized machinery, we provide customers with high-performance solutions in the infrared spectrum, meeting specific needs for IR optics, complex opto-electromechanical assemblies, starting from an idea or technical design.